Digital Ship

The new standard

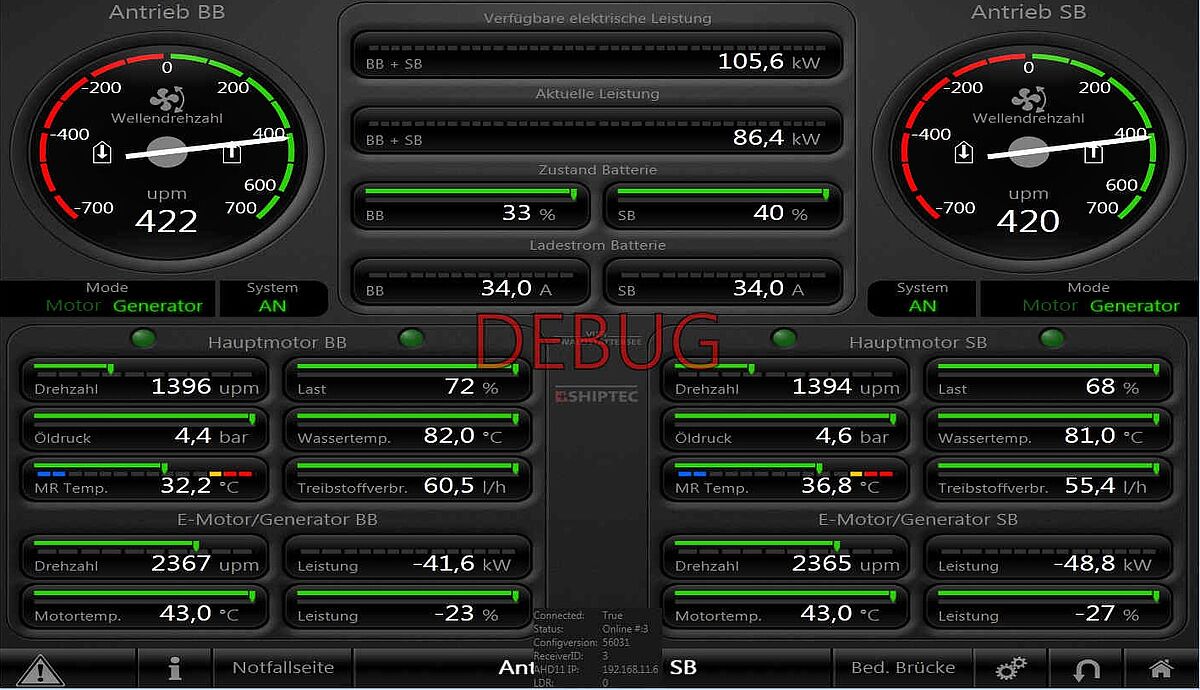

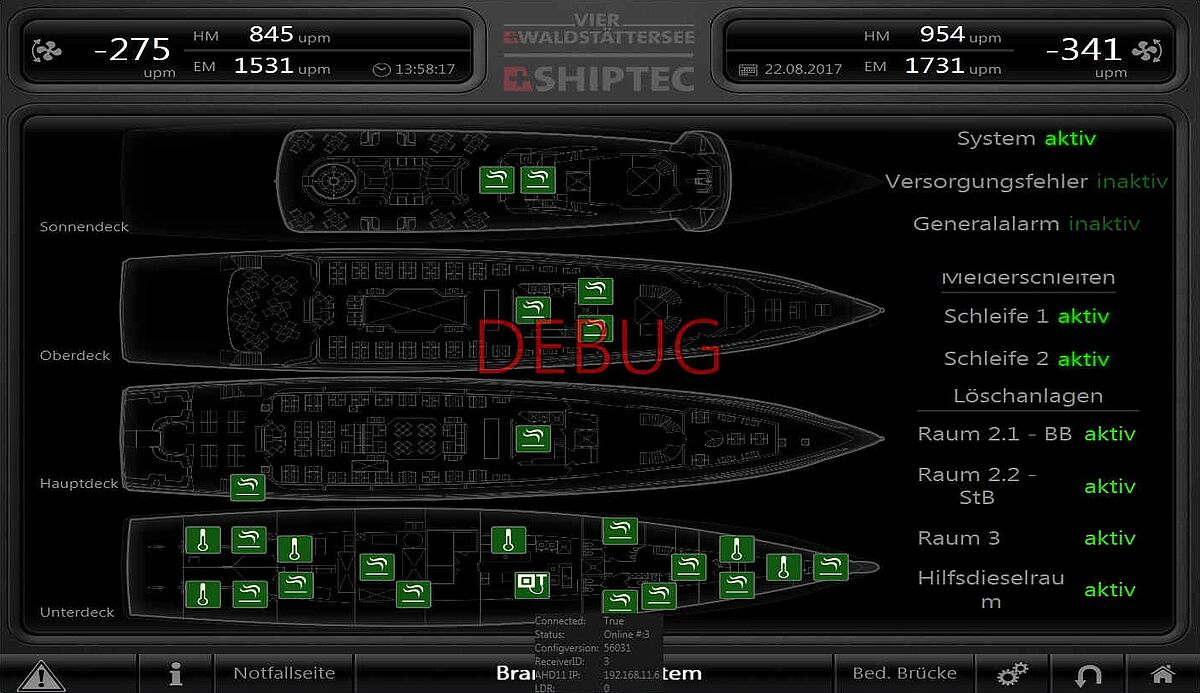

Networking the individual technical on-board systems into an integrated system and having subsequent data transfer to shore allows us to create the ‘smart ship’. Thanks to the evaluation of ship operating data, optimisation potential for maintenance and planning can be implemented on an ongoing basis.

All ship-relevant parameters, such as drive data, power management, cooling cells, the bilge system, etc. can be monitored externally. The freely programmable user interfaces provide the necessary flexibility. With the help of automated analyses and remote analyses carried out by our engineers, technical operating parameters are optimised and potential causes of faults are detected at any early stage. Remote access can be configured according to the operator’s needs, so that the relevant operating information can be viewed at any time. The integrated logging function allows a technician to download data from the system onto an external computer for graphic display and analysis.

An alarm can be activated via SMS for defined error messages. Depending on the area of application, data transfer is either via GPRS, long range WLAN or satellite. With the help of automated analyses and remote analyses carried out by our engineers, technical operating parameters are optimised and potential causes of faults are detected at any early stage.

Any potentially emerging changes in the behaviour of the ship’s system can be detected early with the help of long-term recordings, which enables preventative measures to be taken. This allows the crew or technician on-site to be provided with assistance for efficient troubleshooting. This guarantees the availability of the ship and optimal operations.

![[Translate to Englisch:] [Translate to Englisch:]](/assets/_processed_/c/e/csm_Metallbauarbeiten_03_e8db8f3bf5.jpg)